Heat Treatment Definitions

Haba Stress Engineering

WHAT IS HEAT TREATMENT

WHAT IS HEAT TREATMENT

One of the purposes of heat - treating is to relieve stresses caused when two pieces of metal are joint together by welding. As the metal in welded area raised to fusion temperature, the surrounding metal tends to expand but is restrained by the unheated areas adjacent to the welded joint. As a result, the heated portion is place under a compression stress, the magnitude of which may approach and sometimes exceed the yield point of metal.

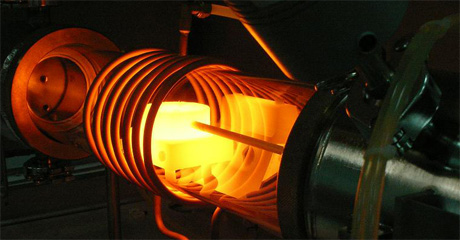

Upon the cooling, the heated areas contract and set up reverse stresses, with the result that when cooled to room temperature the metal in the weld area is under constant Tensile Stress. To avoid internal stresses, stress-relieving equipment is equally applicable for normalizing, annealing and pre-heating, and electrical heating apparatus is proving successful in carrying out stress relieving requirements, for temperature up to 1100C.

Control of temperature is an important feature and temperature in range of 600C to 950C required to heat-treat the materials can be arrived at a specified rate of temperature increase. The heat can then be adjusted to maintain the area being stress relieved at the temperature and period specified. Reducing the temperature at any given rate controls the cooling period.

QUESTION & ANSWER

Question

Why is post-weld heat treatment (stress relieving) sometimes necessary for welded vessels?

Answer

During the welding process, the two metal pieces being joined are subject to extreme temperatures and can cause the crystalline structure of the metal to pass through various metallurgical phases. As a result, hardening (and embitterment) of the metal can occur to varying degrees (usually dependent on carbon content). Heat treatment is designed to reduce the hardness in the heat affected zone of the metals and also increase ductility in these sections. Various pressure vessel codes contain the specifics regarding the procedures for post-weld heat treatment.

Heat is usually held for one hour per inch of thickness of the metal. The temperature used is based on the "P-number" of the metals. P-numbers are assigned based on the chemical composition of the metals. Holding temperatures can range from1100-1350 °F (593-732 °C).

Our personnel will supervise any stress relieving operations that the clients desires, making provision for yield at high temperatures and secondary stressing when cooling at the degree and duration of soaking temperature necessary for the material.